Date Code (D/C) expiration is a very common occurrence, as the time when customers receive the goods often exceeds the official quality guarantee period promised by the original manufacturer.

Many original manufacturers officially define the quality guarantee period as 1 year or 2 years, but in fact, the effective storage period of chips is much longer than 1 year. So, how long after the D/C expiration can the chip still maintain guaranteed quality and be usable?

1. Shelf Life ≠ Effective Storage Period ≠ Service Life

Shelf Life refers to the quality guarantee period of the chip provided by the original manufacturer, usually calculated from the time the chip leaves the factory (exits the original manufacturer's warehouse). To digest the produced products as quickly as possible and avoid disputes caused by quality issues, the original manufacturer will not promise an overly long quality guarantee period, even though the expiration of the D/C will not affect the quality of the chip at all.

Effective Storage Period refers to the maximum period during which the batch quality of the chip can meet the quality requirements when stored under specified storage conditions. After exceeding this period, the components need to undergo an "expired re-inspection" before mounting to re-determine their usability. This is a reference for whether the chip can be used after expiration.

Service Life refers to the expected time during which the chip can operate stably and meet performance requirements in the actual working environment.

2. Storage Conditions Are the Key Factor Determining Chip Usability for the Effective Storage Period

In an ideal environment (such as sealed, moisture-proof, temperature ranging from 15-25°C, and free from static electricity and dust), semiconductor devices can maintain stable performance for a long time. Research by Texas Instruments shows that the storage life of its chips can reach 15 years without significant degradation. Even under normal conditions, properly stored chips have a low risk of performance degradation within 4-5 years. On the contrary, if the storage environment is humid (humidity > 60% RH) or high-temperature, it may accelerate pin oxidation, material deterioration, or parameter drift, increasing the probability of failure.

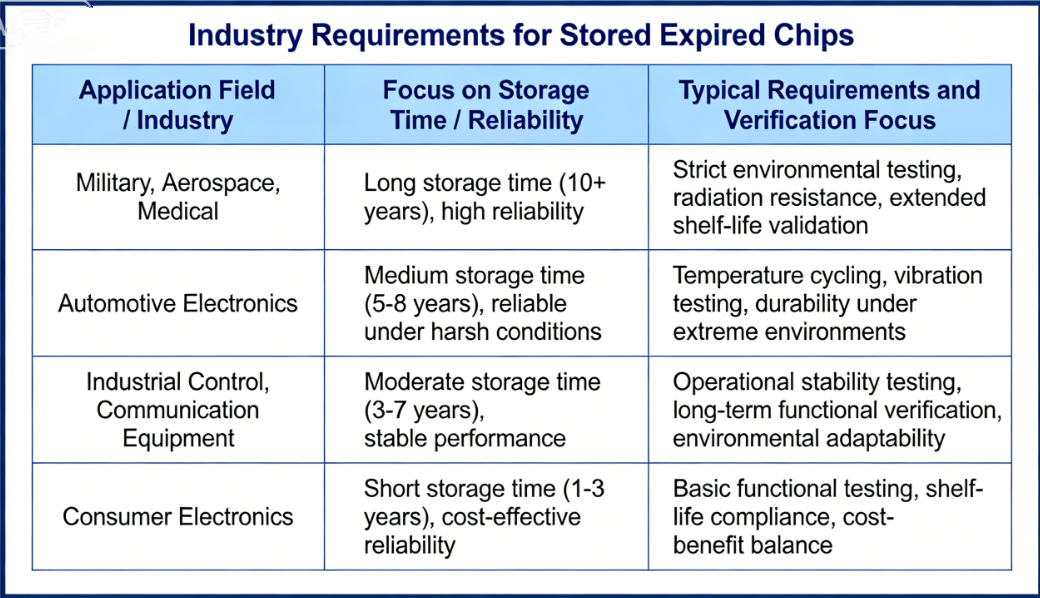

3. Different Industries Have Different Requirements for Storage Time

Although the chips themselves may have a "long lifespan", different industries have different acceptance levels for using stored chips. This mainly depends on the reliability level of the product and the severity of the consequences of failure.

Therefore, how long the chip's Date Code has expired is not the key point. The key points are whether the chip's storage conditions meet the requirements, whether the storage time meets the industry standard requirements, and whether the sampling test passes.

Whether you are an electronic component trader, a PCBA factory, or an EMS provider, you are welcome to contact us if you have any questions about the usability of chips based on their date codes.