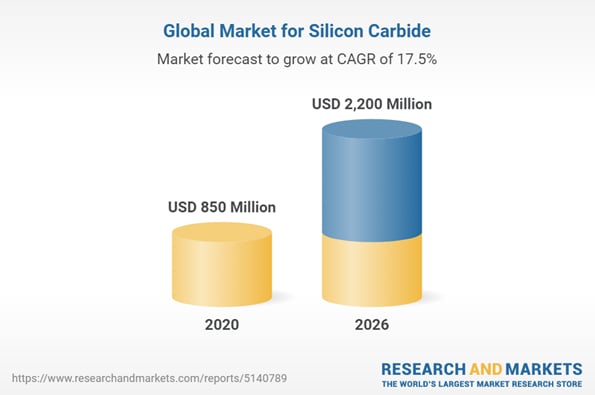

Interest in SiC chips has surged, particularly for their utility in fast-charging, battery-powered electric vehicles. Chipmakers have responded in kind, increasing SiC production capacity and opening new plants. Government financial incentives like the CHIPS+ Act are an additional stimulus for companies to invest in power semiconductors for industrial and automotive applications.

SiC global market value. Image used courtesy of GlobeNewswire

Wolfspeed Builds the World’s Largest Fab in North Carolina

Following the opening of Wolfspeed's Mohawk Valley Fab in Marcy, New York, earlier this year, the company recently announced another expansion to a nearby site in Durham. The new plant is located in Chatham County, North Carolina. Wolfspeed intends to produce 200-mm SiC wafers at the site.

Rendering of the new Wolfspeed materials plant in Chatham County, North Carolina. Image used courtesy of Wolfspeed

The first $1.3 billion investment on the 445-acre site, conveniently located just 40 miles from Durham, is scheduled to take place in 2024. The total investment could reach $5 billion by 2030, creating 1,800 new jobs. The facility will eventually occupy one million square feet on the 445-acre site, making it the world's largest SiC materials facility.

The industry leader in advanced semiconductor manufacturing hopes to support its newly-established operations with funds from the CHIPS+ Act. In addition to receiving investments from the local government, Wolfspeed has received local talent and expertise from the North Carolina Agricultural and Technical State University through the Wolfspeed Endowed Scholars Program, a two-year-long partnership that started in 2020.

ST Secures European SiC Leadership

Another company looking to strengthen its supply chain resilience is STMicroelectronics, which has, according to EE Power, just announced the opening of a new 200-mm fab plant in Catania, Sicily, in Italy.

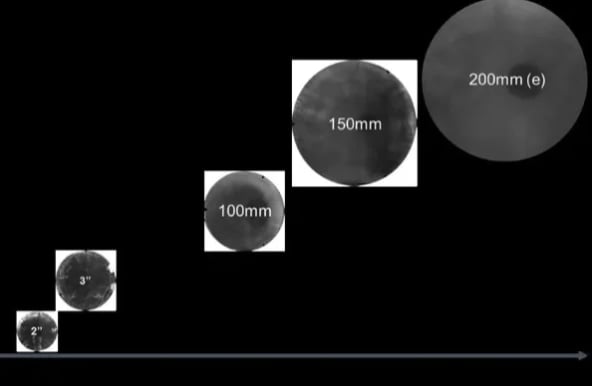

The idea behind ST Microelectronics' European factory is not only to make the in-demand 200-mm chips but also to reinvent the manufacturing technology by working on SiC wafers with new thicknesses and epitaxy based on trench technology.

While ST mainly relies on outsourcing for the silicon carbide, the purpose of the new Sicily plant is to develop in-sourcing practices that would make the growth process less reliant on external suppliers.

SiC wafer diameters over the years. Image used courtesy of EE Power

Like other semiconductor manufacturers, ST collaborates with local educators—in this case, the University of Catania—to build a mentoring and educational community of engineers and students working together on advanced power electronics.

SK Siltron Opens New SiC Fab in Michigan

According to TheElec, South Korean-based SK Siltron has announced the impending opening of its SiC wafer factory in Bay City, Michigan, with plans to increase 6-inch SiC wafer production. In 2020, SK Siltron acquired Dupont's SiC wafer business. SK Siltron has plans to expand to 8-inch wafers for power electronics and 120,000 sheets of 6-inch SiC wafers by 2023.

SK Siltron facility. Image used courtesy of SK Siltron and TheElec

SK Siltron will use the new facility to melt silicon, grow it into ingots, and cut the resulting material into wafers.

Onsemi Targets New Hampshire for SiC Site

Hudson, New Hampshire, will be home to Onsemi's new SiC facility, which will employ a vertically-integrated manufacturing process. onsemi claims this new facility will help it bring to market an end-to-end solution for power electronics—from sourcing raw materials to creating marketable, fully-packaged SiC devices. onsemi plans to expand its substrate capacity and invest $4 billion in the next five years to build a resilient supply chain for EVs.