As global demand for semiconductors continues to surge, manufacturers are acting to increase capacity. However, semiconductor manufacturing comes at a price: large amounts of water and electricity consumption and gases (from raw materials) that create hazardous waste.

Until recently, chip manufacturers have focused on striking a balance between power, performance, and cost. In the past several years, however, sustainability has also become a key priority for many facilities as they aim to decarbonize their supply chains.

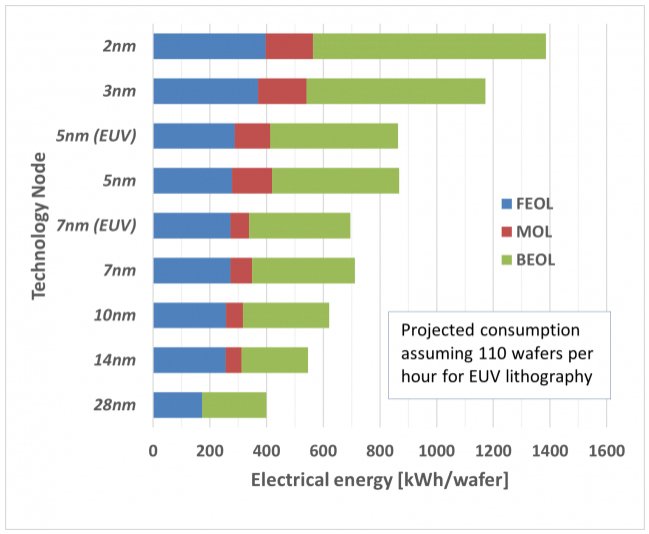

Power consumption of different technology nodes. The energy usage includes the equipment’s average power multiplied by tool times. Image used courtesy of imec

Today, reducing the environmental footprint is not only a corporate initiative but also a matter of compliance—fundamental for long-term business continuity.

imec Shoots for Sustainable Semiconductors

In 2021, imec, a research and innovation center in nanoelectronics and digital technologies, set up its Sustainable Semiconductor Technologies and Systems (SSTS) research program.

ICs contain rare materials that are difficult to recycle because of advanced levels of integration. Image used courtesy of imec

The program evaluates the environmental impact of new technologies (particularly CMOS technologies), identifies high-impact problems, and determines potential solutions. imec’s software tool is able to estimate energy consumption, water usage, and greenhouse gas emissions for present and future technologies. By assessing the environmental impact from the outset, businesses can make informed choices about future technologies.

imec hopes its SSTS program can inspire action, whether it be increased use of renewable energy, recycling, or alternative materials and processes. At Future Summits 2022, the organization announced that its SSTS program succeeded in bringing together various stakeholders of the semiconductor value chain.

Swansea University Announces Net Zero Goals

A new research and innovation facility at Swansea University in South Wales has received nearly $2.7 million in funding for its new project. The Semiconductor Innovation for Net Zero (SIN_0) project is focused on using semiconductors to advance the net-zero agenda and societal decarbonization.

The SIN-0 project will be housed at the Centre for Integrative Semiconductor Materials (CISM). CISM was created to focus on creating semiconductor technologies such as advanced solar cells and efficient power electronics. With the new funding, SIN-0 aims to deploy and test emissions reduction strategies, energy generation and storage, and resource and waste stream management.

Rendering of the Centre for Integrative Semiconductor Materials (CISM), Swansea, Wales. Image used courtesy of CISM

SIN-0 intends to decarbonize advanced research infrastructures like CISM. It is just one of nine projects at U.K. universities focused on reducing the carbon footprint of research facilities.

TI Aims for Sustainability in New 300-mm Wafer Fabs

Texas Instruments (TI) has begun construction of its new 300-m semiconductor fabrication plants in Sherman, Texas. The $30 billion investment includes plans for four fabs to help meet the demand for analog and embedded processing chips. Because TI has a long-standing commitment to sustainable manufacturing, the new fabs will be designed to meet the Leadership in Energy and Environmental Design (LEED) Gold building rating.

TI leaders break ground on the new Sherman, Texas, site. Image used courtesy of Texas Instruments

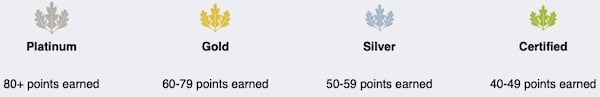

LEED is a green-building rating system that helps developers meet global sustainability standards while reducing costs and improving efficiency. To achieve certification, projects earn points for addressing issues surrounding energy, water, waste, transportation, materials, and more. With LEED's Gold rating, TI's Sherman fabs are designed to protect natural resources and promote sustainability.

LEED certification ratings. Image used courtesy of the U.S. Green Building Council

Shrinking the Carbon Footprint of Semiconductor Manufacturing

Semiconductor-based technology will be critical to many initiatives to mitigate the impacts of climate change. However, the manufacturing industry can also work to reduce the environmental impact of producing chips.

Companies and organizations like imec, Swansea University, and TI are blazing a trail with their respective focuses on reducing water use, their transportation footprint, and the use of hazardous chemicals.